Water pumps are essential in practically every home, business, and industry. We benefit daily from the hard work of pumps in almost every product we purchase. Because of their usefulness, different types of water pumps are designed to be highly specialized in the applications they are used in. In this article, we will discuss the different types and applications of water pumps used in the home and industry.

What is a water pump?A water pump is used to transport water from one location to another. To suck water in so that it can be expelled, a pump must be able to rapidly alter pressure within a system. How a water pump achieves this pressure change is what allows certain pumps to be more beneficial to certain applications than others. Various mechanisms and movements are used to pump fluid through a system. Some pumps, for example, use reciprocating movement of a diaphragm to alter the pressure on either side of the pump. Others use rotational movement to seal off certain sections of the pump chamber, thus altering the pressure inside.

While all water pumps move water, they are needed for many different reasons. For example, a boat must use a water pump to rid the hull of water when it builds up. A water booster pump, on the other hand, is used to increase water pressure inside a home. Regardless of the application of a water pump, the goal is the same: to move water from point A to point B.

Common types of water pumpsThere are two main categories of water pumps: positive displacement and centrifugal. Both types contain characteristics that tailor to specific water pumping needs.

Positive displacement pumps

A positive displacement pump closes off a predetermined amount of fluid so that it can be moved through a system. They move fluid with either reciprocating or rotary movement of the pump’s internals. Reciprocating pumps utilize a diaphragm, pistons, or a plunger, while rotary pumps use gears or cogs.

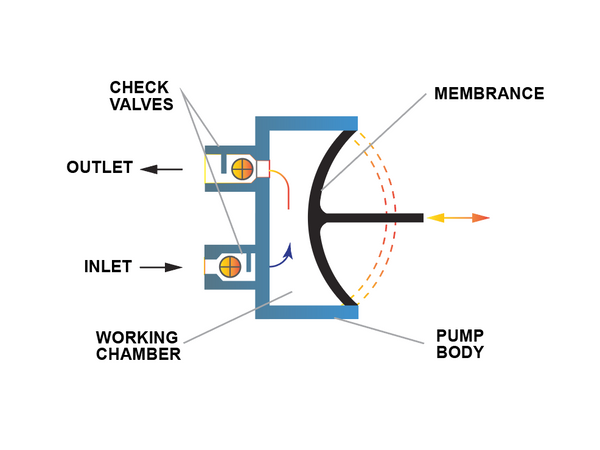

Diaphragm pumps

Diaphragm pumps, also known as membrane pumps, use the reciprocating movement of a diaphragm to pump fluid through a system. They are excellent self-priming pumps, and they excel at running dry for short periods without damaging themselves. The chamber of a diaphragm pump contains non-return check valves to force liquid to flow in only one direction and prevent backflow.

Diaphragm pumps are excellent at handling highly viscous fluids, making them perfect for wastewater treatment applications. They are often called “mud hogs” because of their ability to handle thick fluids that many other pump types cannot. Diaphragm pumps are also capable of pumping gases and mixtures of liquids and gases. They are not hermetically sealed, meaning they do not prevent gases from leaking out, so they should not be used to transport toxic gases.

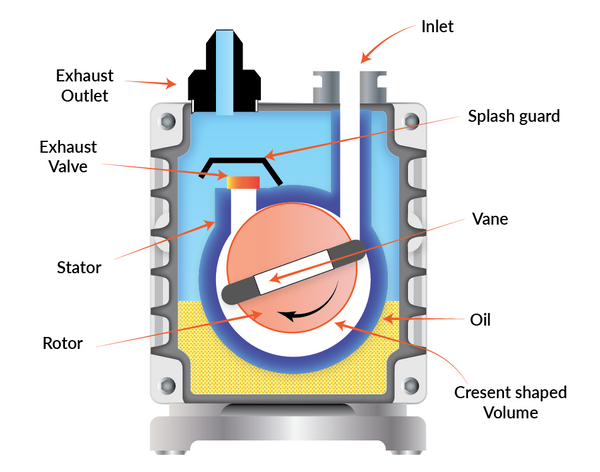

Rotary vane pumps

As the name suggests, rotary vane pumps use the rotational energy of vanes to move fluid or gasses through a system. The vanes in these pumps create the seal that allows pressure to build up inside the system. They are used in both high-pressure and medium-pressure applications. High-pressure rotary vane pumps are often used in automobile applications, such as power steering, air conditioning, and automatic transmissions, while medium-pressure vane pumps are commonly used for espresso machines and fountain drink dispensers.

Learn more: What is a rotary vane pump?

Peristaltic pumps

Peristaltic pumps, also known as roller pumps, use the rotational movement of rollers to push fluid through flexible tubing. When pushed through a peristaltic pump, fluid never comes into contact with the pump’s components. Because fluid cannot wear at the pump’s internals, peristaltic pumps are one of the lowest maintenance pump types. The most regular maintenance task for peristaltic pumps is replacing the tubing once it has worn out.

To create a vacuum, a roller pushes down on an empty section of the tubing, creating pressure to draw fluid into the pump. Once this fluid has entered the tubing, a second roller rotates behind the fluid, pushing it toward the pump’s outlet. Another roller creates a vacuum on the empty section of tubing, and the cycle continues. The more rollers a peristaltic pump has, the greater its output will be. These rollers can only rotate in one direction, which is why peristaltic pumps are referred to as one-way pumps. This means fluid can only be drawn in and pushed out in one direction, so they are inherently immune to backflow.

Learn more: What is a peristaltic pump?

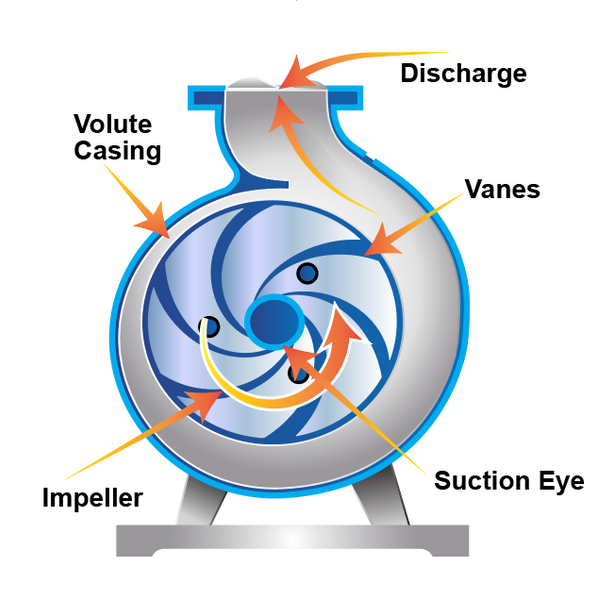

Centrifugal pumps

Centrifugal pumps pump water by rotating an impeller that pushes water through the pump housing. Unlike some positive displacement pumps, centrifugal pumps should never run dry, as they will quickly overheat and damage the pump components and seals. Viscous fluids reduce the efficiency of centrifugal pumps, so they are primarily used to pump relatively clean water and other less viscous fluids. One disadvantage of centrifugal pumps is that they must always be primed. Because they cannot run dry, they must be filled with whatever liquid they will pump before they begin operating. Centrifugal pumps are commonly used in various industrial and home applications, including irrigation systems, chemical plants, oil and gas operations, and food and beverage systems.

In most pump applications, different types of pumps can accomplish the same task. The context of the system determines which type of pump is best for a specific application. Here are some common pump applications for homes, RVs, and boats.

Sump pumps

Sump pumps detect rising water levels in a basement and pump the water to a drainage area outside a home. A sump pump’s float switch or pressure switch detects rising water levels or pressure. Once a threshold water level or pressure is reached, the switch sends a signal to the pump, which then activates. The pump continues to run until the pressure drops below a lower threshold. At this point, the pump will shut off and wait for the higher limit to be met again.

Four primary types of pumps can be used as sump pumps. These include submersible, pedestal, battery-operated backup, and water-powered backup pumps. Submersible sump pumps operate in water, leading to a shorter lifespan, while pedestal pumps operate outside the basin, which improves lifespan at the cost of increased noise and worse efficiency. Battery-operated backup sump pumps provide security during electrical outages by using a battery to power the pump, while water-powered backups utilize water pressure in emergency situations.

Learn more: What is a sump pump and how does it work?

Water booster pumps

Water booster pumps improve the water pressure for an entire home or building. They are needed when homes experience plumbing issues, city water pressure is low, a water source is a long distance away from its points of use, or water treatment systems decrease the overall system pressure. If the flow rate in your home does not meet the rate at which you use water, a water booster pump is needed. Homes with multiple stories may also need a booster pump to allow an adequate flow rate in areas where water must travel uphill.

Learn more: How to calculate flow rate

Water booster pumps utilize either an impeller or an oscillating diaphragm to improve the flow rate in a home or building. Much like how a fan moves air by spinning blades, an impeller moves water through the pump through rotary movements that increase the water pressure inside the pump’s chamber. As pressure ebbs and flows, water is sucked into the pump and forced out in a cycle. An oscillating diaphragm achieves the same result while using a reciprocating diaphragm rather than the rotary motion of an impeller.

Learn more: What is a water booster pump?

Well pumps

Well pumps are the heart of a home well water system. When the volume of water in a well water storage tank drops below a preset lower threshold, a pressure switch triggers the pump until the tank is filled to an upper threshold. Well pumps can be installed in a well itself, a home, or an outbuilding. They are designed to run only when the storage tank drops below the preset threshold, so they do not run for extended periods of time. If the pressure switch fails, however, a pump may run longer than it can tolerate, leading to pump damage.

Many types of pumps can be used in wells, and they are each more effective in specific applications. For example, submersible well pumps, the most used well pump, can be used in practically any well, but they are difficult and expensive to maintain. Jet well pumps, on the other hand, can only work in wells up to 110 feet deep, and they lose efficiency as the depth increases. Centrifugal well pumps, the least common type, are only used in extremely shallow wells, as they are only useful in wells shallower than 25 feet. However, they are inexpensive and simple to maintain.

Learn more: What is a well pump and how does it work?

Demand pumps

Demand pumps, also known as delivery pumps, connect a water storage tank to a faucet or other water outlet. When a faucet or other fixture is opened, water pressure in the system drops, and the demand pump kicks in. Once the pressure reaches the desired amount, the demand pump switches off and waits to sense another drop in pressure. You will commonly see demand pumps used in RVs, well water systems, and reverse osmosis systems, where additional pressure is needed for water to reach its point of use.

Learn more: What is a demand pump and how does it work?

Bilge pumps

Bilge pumps rid a boat’s hull of built-up water. A float switch detects when water levels have risen above a predetermined limit, switching the pump on once the bilge has filled with enough water. Bilge pumps prevent disaster when small leaks arise, granting enough time for a repair to solve the issue. Even in large scale leaks, bilge pumps are essential in buying enough time for help to arrive.

Four main types of pumps are used as bilge pumps: centrifugal, electric diaphragm, reciprocating, and manual. The volume of water each pump can handle varies greatly, so the size of a boat often determines which pump type should be used. For example, large ships will take advantage of multiple centrifugal bilge pumps, while a small recreational boat will often only need an electric diaphragm or reciprocating bilge pump. Manual bilge pumps are only used in extremely small-scale boats, such as kayaks and canoes.

Learn more: What is a bilge pump and how does it work?

RV water pumps

RV water pumps are used to move water from an RV water storage tank to the vehicle’s sinks, toilet, and shower. RV water pumps are 12V pumps so that they can hook up to the RV’s battery. They sense pressure drops in the RV’s plumbing system when a faucet is opened, supplying water only when needed. RV water pumps can either be diaphragm or centrifugal. Centrifugal RV pumps are far less expensive than diaphragm pumps, while the latter is more efficient and reliable.

Learn more: What is an RV water pump and how does it work?

Reverse osmosis booster pumps

Reverse osmosis booster pumps aid water pressure in cases where it is too low for a reverse osmosis system. RO systems require a minimum of 50 psi to operate optimally, making a booster pump essential for homes with low water pressure. An RO booster pump can save homeowners many gallons of water per month by improving the overall efficiency of the reverse osmosis system, reducing the amount of wastewater produced.

Learn more: What is a reverse osmosis booster pump and how does it work?

Reverse osmosis permeate pumps

Reverse osmosis permeate pumps improve the performance of a reverse osmosis system by using the RO system’s wastewater as energy. When water flows through an RO membrane, the contaminants become separated from the filtered water, also known as the permeate. The reject water, or brine, flows down through the drain line. On its way through the drain line, the brine collects in the chamber of the permeate pump until it activates a piston. This piston pushes the permeate through the pump outlet and into the RO storage tank. Permeate pumps improve the performance of a reverse osmosis system, reducing the amount of wastewater by as much as 80% in some cases.

Learn more: How a permeate pump works with a reverse osmosis system

If you have any additional questions, please do not hesitate to contact us.