A bilge pump is one of the most crucial safety features of a boat. Without a bilge pump, excess outside water or leaks can cause a boat to flood or sink. Consequently, these pumps save lives, making them essential to any vessel. There are many types of bilge pumps on the market, and each of them discharges water with a different method than the others. Because of this, selecting a bilge pump for your boat or marine application can be difficult. Below you can find information about what bilge pumps are, how they work, the types of bilge pumps, and how to perform maintenance on your bilge pump.

What is a bilge pump?A bilge pump is a marine pump designed to clear water out of the bottom of a boat’s hull, also known as the bilge. This water may be the result of rain, leaks, splashes, cleaning, or coolers that drain into the bilge. Bilge pumps are rated by the volume of water they can remove in one hour, and each type of pump possesses different ratings at which they are available. These pumps can prevent small leaks from sinking a boat, giving more time for a diagnosis and resolution to be reached. Even for large-scale leaks, bilge pumps can buy more time for help to arrive.

Learn more: How to choose the right bilge pump for your boat

How does a bilge pump work?Automatic bilge pumps use a float switch to activate the pump once water pools above a predetermined level. Once the switch is activated, the pump kicks on to remove the water from the bilge until it is dry. Once the bilge is free of water, the switch deactivates the pump until the water reaches the activation level again. This feature prevents the pump from running constantly while also protecting the boat from built-up water. Some bilge pumps use rotational energy to force water out of a boat, and others use suction to draw water in and push it out. While some older boats use manual bilge pumps, modern boats make use of automatic bilge pumps. Learning how each pump type deals with water can help you select the best one for your boat.

Where are bilge pumps located?Depending on the type of bilge pump in a boat, the pump can be located at the bottom of the bilge or outside of it. Submersible bilge pumps are always located at the lowest point of the bilge because they can only operate underwater. Diaphragm bilge pumps are installed above the bilge away from the water. The hoses for these pumps are lower than a submersible pump can be installed, so they can remove more water than a submersible pump. As a result, these are often referred to as “drying pumps” and are often used in conjunction with a submersible pump.

The most important factor for the location of a bilge pump is its accessibility. Bilge pumps must always be accessible for routine maintenance, inspection, and testing. If your bilge pump is located in a hard to access area, consider relocating it to a more accessible one.

Types of bilge pumpsThere are three main types of bilge pumps: centrifugal, electric diaphragm, and reciprocating. Each type has advantages and disadvantages over the other pumps for certain boat sizes and applications. Some also come in manual configurations that are ideal for small recreational boats.

Centrifugal bilge pumps

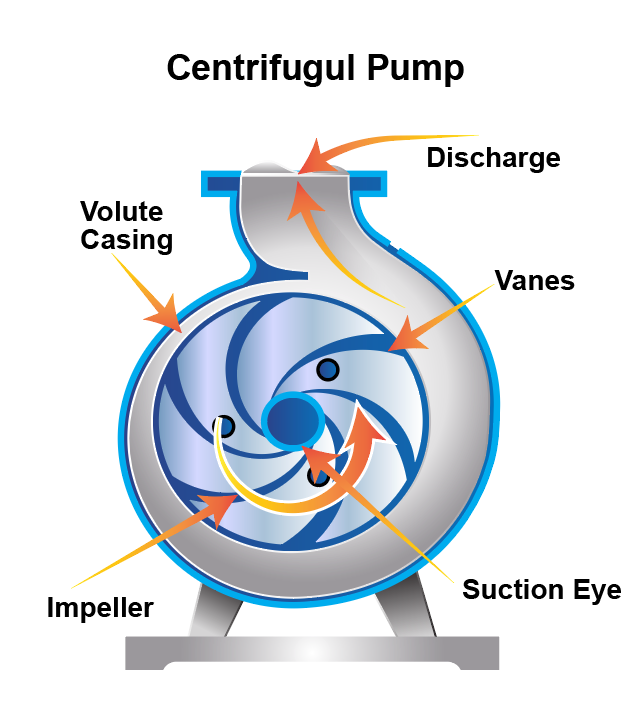

Centrifugal bilge pumps are submersible pumps that use an impeller to increase the kinetic energy of incoming water so that it can be pumped out. When water enters the impeller, the impeller’s rotational force increases the water’s speed. Around the impeller is a diffusion ring with fixed blades. These blades convert the speed of the water into pressure, allowing the water to be pumped out of the boat. Unlike diaphragm and reciprocating bilge pumps, centrifugal pumps are not self-priming, and they must be submerged to operate. The simple design of these pumps makes maintenance simpler than for other pump types.

When water is discharged from the centrifugal pump, the pressure inside the casing drops to draw water into the eye of the impeller. This means the pump must be primed with water before it can draw water in on its own. This feature also prevents centrifugal pumps from removing all water from a boat’s bilge. To remove all water, a diaphragm or reciprocating bilge pump should be used.

Centrifugal bilge pumps can handle large volumes of water, and they are typically less expensive than other pump types. Sizeable marine operations, such as large ships, use centrifugal pumps with multiple impellers to discharge the high volumes of water that the boat intakes.

Advantages of centrifugal bilge pumps

- Can handle large volumes of water

- Inexpensive

- Can tolerate some debris

- Simple maintenance

Disadvantages of centrifugal bilge pumps

- Ineffective at pumping water uphill

- Must be submerged

- Not self-priming

- Do not remove all water from the bilge

Electric diaphragm bilge pumps

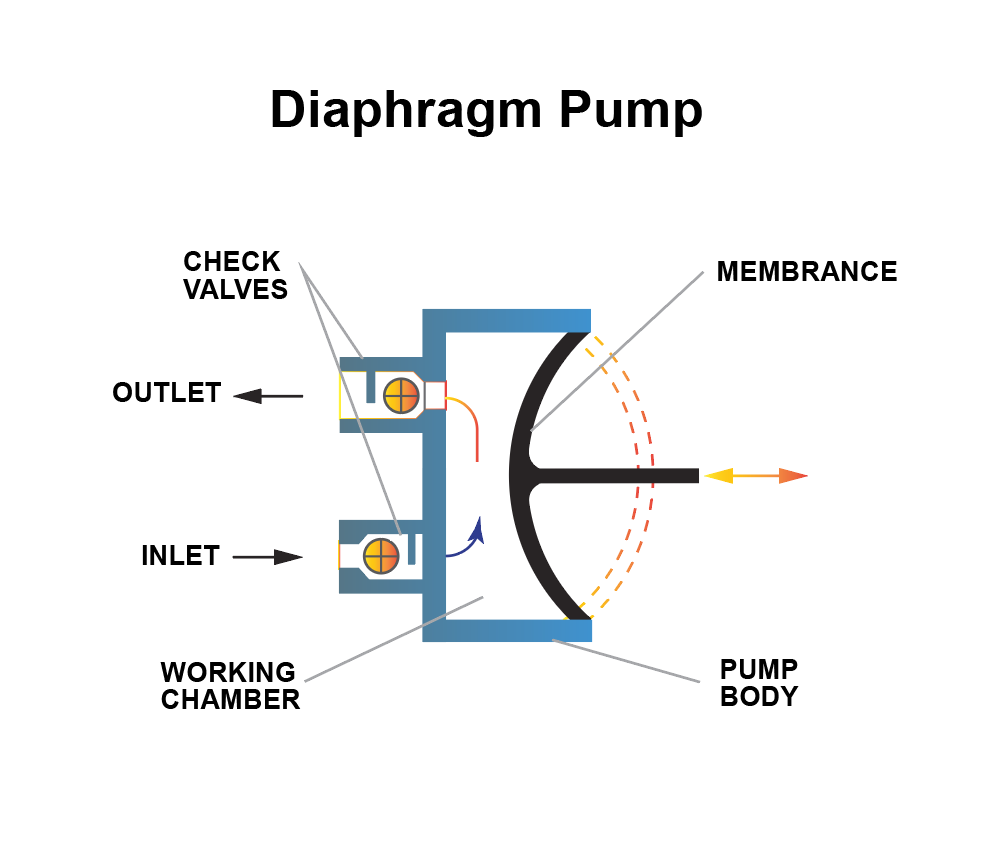

Electric diaphragm bilge pumps are self-priming positive displacement pumps that use a diaphragm to draw in and displace water. These pumps create suction to draw in water as the diaphragm opens and discharge it when the diaphragm closes. Diaphragm pumps are better at pumping water uphill than centrifugal pumps, and as a result, they can remove all water from a boat’s bilge. Unlike other pumps, diaphragm bilge pumps can be mounted away from the bilge, making them less prone to damage than other pump types. Consequently, diaphragm bilge pumps have a longer lifespan than most centrifugal and reciprocating pumps. There are multiple types of diaphragm bilge pumps, including single-diaphragm and double-diaphragm configurations.

Single-diaphragm pumps contain one diaphragm that draws water in and discharges it as the diaphragm moves around. This is the standard design for diaphragm pumps, but the flow rate is not as high as double-diaphragm pumps.

Double-diaphragm pumps have two connected diaphragms that move in conjunction with each other. As one diaphragm opens to let water in, the other one closes to let water out. This allows for more water to be displaced by the pump and generates a more consistent flow rate.

Electric diaphragm pumps cannot handle debris entering the pump’s chamber. Any debris that gets stuck between the diaphragm and the pump’s walls has a high likelihood of damaging the pump. A filter must be installed before the pump’s inlet valve to ensure debris cannot enter. Diaphragm bilge pumps cannot handle the large volumes of water a centrifugal pump can. Consequently, diaphragm pumps can only be used on small to medium-sized boats and other small marine applications.

Advantages of electric diaphragm bilge pumps

- Self-priming

- Can be mounted away from the bilge

- Better uphill pumping than centrifugal pumps

- Little maintenance

Disadvantages of electric diaphragm bilge pumps

- Cannot handle much debris

- Smaller capacity

Reciprocating bilge pumps

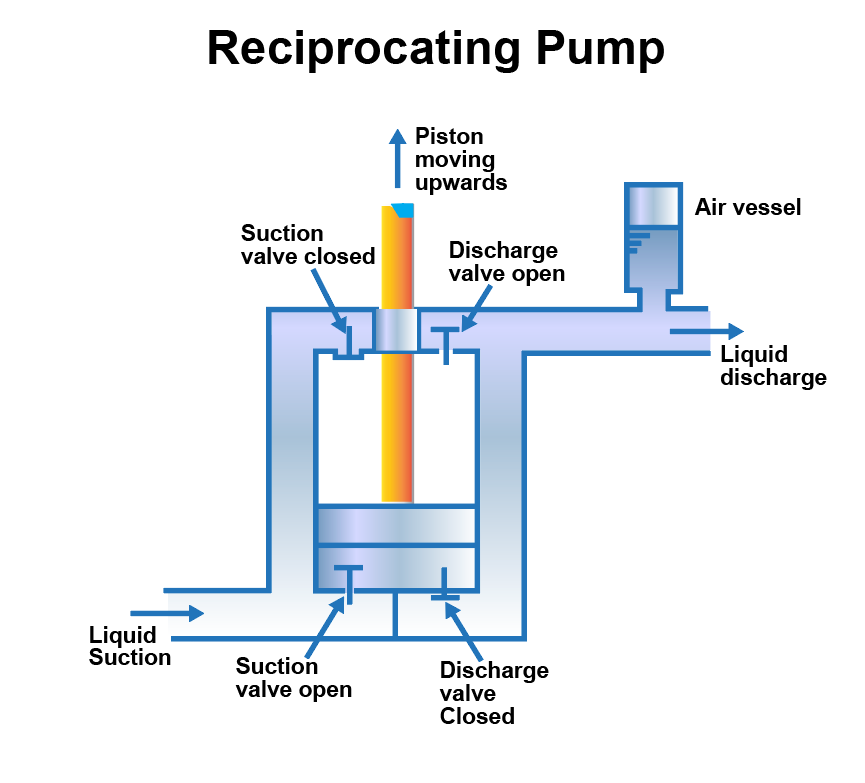

Reciprocating bilge pumps, also known as piston bilge pumps, are self-priming positive displacement pumps that are more effective at uphill pumping than centrifugal pumps. These pumps draw water in on one side of the piston and discharge it from the opposite side. Both sides of the piston contain a suction valve and a discharge valve. As the piston moves up, the top suction valve opens to allow water in. Simultaneously, the upper discharge valve remains closed, and the lower discharge valve opens to allow the water beneath the piston to escape. When the piston moves down, the lower suction valve opens, the bottom discharge valve closes, and the upper discharge valve opens. The water that was previously drawn in above the piston is now discharged.

Reciprocating bilge pumps are even less tolerant of debris than diaphragm pumps. When debris enters the pump, it lodges between the piston and the pump’s wall. This can clog the discharge and suction valves and lead to pump failure. To counteract debris, a filter must be installed in front of the suction valve. In addition, reciprocating bilge pumps are not capable of displacing as much water as other pump types. As a result, reciprocating bilge pumps can only be used for small boats and other marine applications.

Advantages of reciprocating bilge pumps

- Can handle fluids more viscous than water

- Self-priming

- Better uphill pumping than centrifugal pumps

Disadvantages of reciprocating bilge pumps

- Cannot handle debris

- Smaller capacity

Manual bilge pumps

Manual bilge pumps are hand water pumps used for non-motorized boats. Most manual bilge pumps output a maximum of 20 gallons per minute, and they should not be used for motorized marine applications. Typical applications for these pumps include kayaks, canoes, and dinghies.

Advantages of manual bilge pumps

- Perfect for non-motorized marine applications

- Does not require electricity

- Inexpensive

Disadvantages of manual bilge pumps

- Extremely limited applications

- Requires manual pumping

Learn more about water pumps: Well pumps | Rotary vane pumps | Grundfos Scala pumps | RV water pumps

Bilge pump maintenancePerforming regular checkups on your bilge pump is critical for both your safety and the lifespan of your marine pump. Maintenance not only saves money on a new pump, but it can also spare you from costly boat repairs caused by flooding. There are several checks you can perform to extend the life of your bilge pump.

1. Test the pump

Before heading out on the water, you should ensure that your bilge pump is working properly. While this may seem like a mundane task, it can save you from headaches and danger should the pump fail while on the water. To test the bilge pump, pour a few gallons of water into the bilge. If the pump activates and removes the water, the pump is working correctly. Should the water remain stagnant in the bilge, either there is not enough water to activate the pump or the pump needs maintenance. If your pump is not working properly, do not go out onto the water.

2. Check the wiring and float switch

While on the water, you should be able to hear the bilge pump running. If you hear the pump running constantly, either too much water is getting into the bilge, the switch is faulty, or the wiring is incorrect or broken. If your pump is running constantly, inspect all wiring for corrosion or breaks. If the wiring appears functional, ensure the float switch is free of debris. If both the wiring and the float switch operate correctly, check for leaks or other causes of excess water in the bilge.

3. Clean the pump

Water that makes its way into the bilge is often full of unwanted gunk such as algae, debris, and dirt. While some bilge pumps can deal with these nuisances, they can wear down a pump over time. Bilge cleaners break down built-up sludge on the inside of a pump to keep it running smoothly. They also work while your boat is on the water, so you do not have to worry about rinsing the pump before heading out. In addition to using a bilge cleaner, you should wash the outside of the pump about once every month during the seasons your boat is in use.

4. Check the outlet hose

Outlet hoses are durable, but they should still be regularly inspected for damages and clogs. If only a small amount of water comes out of your hose, it is likely clogged or there is a problem with the battery. If the voltage on the battery is normal and the hose is not clogged, the issue most likely lies within the pump itself.

5. Check the impeller

For centrifugal pumps, the impeller’s inability to rotate is a clear sign of a faulty pump. To test the impeller, shut the power off to the pump and unmount it from the bilge. Attempt to turn the impeller with your hand. If it does not turn and it is free from obstruction, the pump needs to be replaced.

6. Check the filters

The filters that prevent debris from building up in the pump can easily become overwhelmed if not regularly cleaned. Before going out on the water, ensure that all debris is removed from the filters.

If you have an automatic bilge pump with a float switch, the switch will automatically signal the pump to turn on and off. If your pump does not utilize a float switch, you will need to watch the water levels in the bilge and switch the pump on when it needs to be emptied. Submersible bilge pumps cannot run dry, so if you notice the pump remains on when the bilge is drained, there may be a problem with your float switch or pump.

How long do bilge pumps last?An average bilge pump lasts around three to five years. If well maintained, it can last longer, but you will need to ensure the pump is safe each time you go out onto the water. One sign that a bilge pump is reaching the end of its life cycle is a poor flow rate. If a pump is not clogged and it outputs lower volumes of water than normal, it likely needs to be replaced.

Do I need a filter for my bilge pump?A bilge pump inlet screen can protect your bilge pump from damaging debris. These screens are an inexpensive way to avoid an expensive accident not only to the pump, but potentially the entire boat. Inlet screens are also low maintenance. Before heading out on the water, check the screen and remove any debris to avoid clogging.

If you have any further questions, please do not hesitate to contact us.