While they are not a household name, rotary vane pumps play a critical role in everyday life. Whether it be transporting power steering fluid in a car, helping a fountain drink contain the perfect amount of carbonation, or transporting thick liquids without damaging their quality, rotary vane pumps undoubtedly perform a substantial role in many of the products you enjoy daily. In this article, you can learn what rotary vane pumps are, how they work, their advantages and disadvantages, and the different types of vane pumps.

What is a rotary vane pump?A rotary vane pump, also known as a vacuum pump, is a self-priming positive displacement pump that moves fluids and gases with vanes mounted to a rotor inside a cylindrical housing. The liquids and gases are compressed, pressurized, and passed through the pump outlet. Automobile manufacturers use vacuum pumps in numerous applications, such as power steering, air conditioning, and automatic transmissions. The food and beverage industry also uses rotary vane pumps for fountain drink dispensers, espresso machines, and the transportation of viscous liquids. They are also commonly used in the water treatment industry for feeding pressurized water to reverse osmosis filtration membranes.

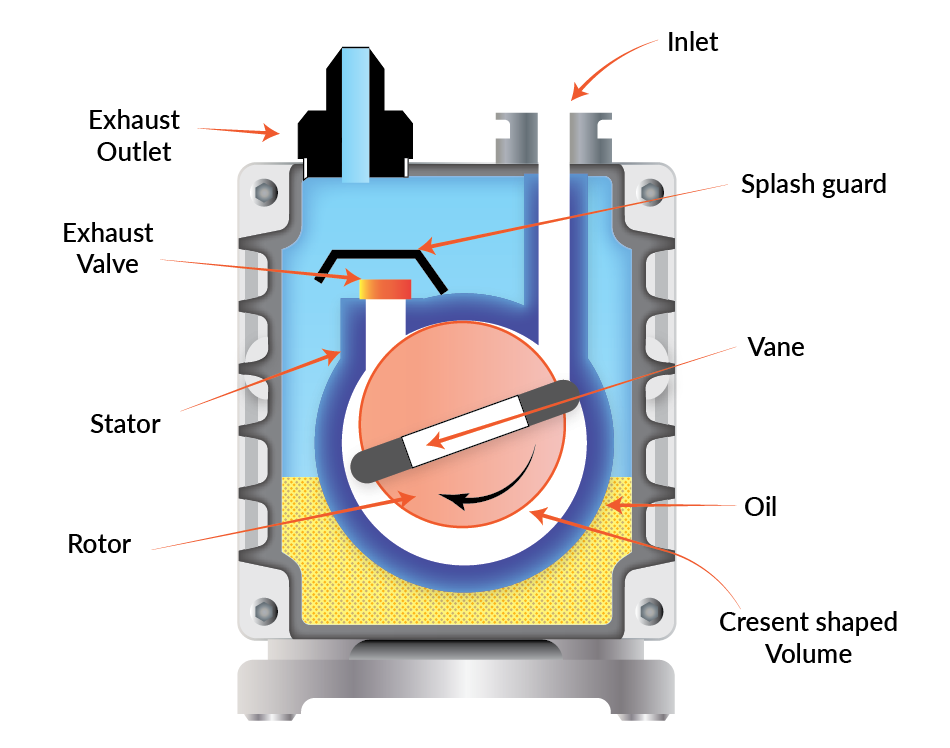

How does a rotary vane pump work?Rotary vane pumps contain two or more chambers that compress, rotate, and discharge gases and liquids. These chambers create a vacuum that pressurizes the contents, allowing them to travel through the pump’s outlet. The vanes slide in and out and turn against the inner wall of the rotor. As the vanes rotate, one chamber forms, and the outlet valve divides the chamber into suction and discharge sides. The fluid enters the suction side of the chamber, where it compresses with each rotation. Once the suction chamber reaches its maximum capacity, the contents are released into the discharge chamber and through the pump outlet. Finally, an exhaust valve prevents backflow by blocking contents that try to reenter the pump.

Are rotary vane pumps centrifugal pumps?No, rotary vane pumps are positive displacement pumps, not centrifugal pumps. Positive displacment pumps work by capturing a predetermined volume of liquid and moving it between the suction and discharge chambers. The seals created by the vanes and the flow of liquids create pressure. Positive displacement pumps can sustain high pressures while utilizing low suction pressure, and they are not affected by the fluid’s incoming pressure. In contrast, centrifugal pumps, like the unit pictured below, create initial pressure that results in flow.

Positive displacement pumps can pump liquids with a higher viscosity than centrifugal pumps can. This is a result of frictional losses inside centrifugal pumps. On the other hand, positive displacement pumps increase in efficiency with more viscous liquids to a certain point.

Uses for rotary vane pumpsHigh-pressure vacuum pumps are commonly used for transporting freon, power-steering fluid, and transmission fluid in automobiles. Medium-pressure rotary vane pumps transport water in espresso machines and carbonated beverage dispensers. While less common than higher pressure pumps, low-pressure rotary vane pumps are used in chemical vapor deposition, a method used to create thin film for semiconductors. Other uses for vacuum pumps include:

- Dust extraction systems

- Industrial furnaces

- Vacuum filtration

- Degassing

- Crystallization

- Distillation drying

The major components of a rotary vane pump are the following:

- Rotor

- Stator

- Vanes (also called blades)

- Cylindrical housing

- Inlet

- Exhaust valve

- Exhaust outlet

- Oil reservoir

- Splash guard

Types of rotary vane pumps

Types of rotary vane pumps

The different types of rotary vane pumps more or less function in the same way, but they can utilize many types of vanes. These vane types include:

- Sliding – vanes slide in and out to draw liquid in through the inlet port and into the chamber

- Flexible – vanes maintain contact with the rotor walls, trapping liquid as the vanes rotate

- External – vanes are fitted into the pump’s casing instead of the rotor

- Rotating – vanes rotate inside the cavity to trap liquids

- Oscillating – vanes draw in liquids with an oscillating pumping motion

Sliding and flexible vane pumps are the most common type of rotary vane pump and are used in various commercial applications. Sliding vane pumps are commonly found near fountain drink dispensers and espresso machines. They transport water into pressurized CO2 tanks and pass heated water through espresso grinds. On the other hand, flexible vane pumps are commonly used in food and pharmaceutical applications. They are effective at transporting viscous liquids, such as creams and liquids, with solids, such as yogurt, without compromising the quality of the product.

Oil-lubricated vs dry-running rotary vane pumpsDry-running and oil-lubricated rotary vane pumps work in a similar way, but oil decreases wear on the pump and enhances the seals formed in the rotor.

Oil-lubricated rotary vane pump operation

Oil-lubricated vane pumps operate like dry vane pumps with a few key differences. They cannot be used in the water treatment industry because of their residual effects on the discharge.

- An oil pipe feeds the cylindrical housing oil, where it coats the vanes and walls to prevent wear.

- The vanes push against the rotor walls, forming chambers that capture air and liquid.

- The captured air and fluid are compressed and transported to a compression chamber.

- When the chamber reaches its maximum compression, it opens and discharges into the oil separator housing

- The oil separator housing removes oil particles from the air or liquid.

- Further filtration removes leftover oil particles.

- The air or liquid is discharged through the outlet.

Dry rotary vane pump operation

Dry vane pumps operate like oil-lubricated vane pumps with a few key differences.

- Dry-running pumps use graphite vanes that contact the inner walls of the rotor. The graphite coats the walls, allowing the vanes to contact them with minimal wear.

- When liquid enters, the vanes trap the liquid in the chamber, where it is compressed, rotated, and discharged.

- Excess air is discharged after the fluid is compressed.

- Unlike oil-lubricated vane pumps, dry-running pumps do not need any post-filtration because nothing has been added to the air or liquid.

Oil is a helpful addition to a rotary vane pump in some cases, but it is not ideal for every application. Oil performs four essential functions in a vane pump:

- Seals between the rotor and vanes

- Forms a second seal between the vanes and chamber

- Cools the pump by dispersing heat

- Protects components from corrosion

Oil provides seals that make vacuum pumps far more efficient than dry-running ones. However, oil can exit with pressurized gases in a pump, making it unsuitable for some applications. Oil traps help mitigate oil expulsion, but pumps will always expel oil regardless of how high-quality the oil trap is.

Benefits of oil in a rotary vane pump

While rotary vane pumps can run completely dry, some units benefit from the lubrication oil provides. The following are benefits oil has on a rotary vane pump:

- Provides a seal that enhances the ability to form a vacuum

- Elongates the lifespan of a pump by preventing wear

- Keeps temperatures cool by reducing friction

- Eliminates impurities and prevents them from damaging the pump

- Prevents pump from corrosion caused by reactions with gas

- Increases the efficiency of the pump by creating more effective seals

Rotary vane pumps have many advantages regardless of the types of vanes inside them.

- Extended lifespan due to durable vanes

- Quiet operation

- Little vibration

- Low maintenance

- Can run completely dry

- Lightweight and compact

- Discharged liquid is not sensitive to changes in viscosity

- Stable flow rate with low pulsation

Rotary vane pumps are excellent at transporting liquids, but their operation does pose some risks and disadvantages.

- Poor durability when in contact with abrasive materials

- Prone to damage when operating with thicker liquids

- Proper filtration systems needed before adding liquids to the pump

- Not suitable for very high pressures

If you have any further questions about rotary vane pumps, please do not hesitate to contact us.